Fiber laser marking technology represents the pinnacle of precision marking solutions for metal components across manufacturing industries. A fiber laser marking machine utilizes concentrated fiber optic laser beams to create permanent, high-contrast marks on metal surfaces, delivering unmatched accuracy and durability. Fiber laser systems provide clear identifying markings without compromising the metal part's structural integrity, unlike older marking techniques. This technology is essential for part traceability, quality control, and regulatory compliance in automotive, aerospace, electronics, and luxury products. Fiber lasers are selected by manufacturers seeking dependable, cost-effective marking solutions that improve operational excellence and fulfill strict industry requirements due to their better wavelength characteristics and energy economy.

Understanding Fiber Laser Marking and Its Advantages for Metal Parts

Fiber laser innovation works through modern fiber optic frameworks that create concentrated laser pillars at ideal wavelengths for metal interaction. These frameworks create short-pulse, high-energy laser bursts that make exact surface adjustments without influencing the fundamental fabric structure.

Superior Wavelength Technology

The 1064-nanometer wavelength created by fiber lasers gives uncommon retention rates over different metal types. This wavelength enters metal surfaces proficiently, making lasting marks through controlled warm interaction. Stainless steel, aluminum, titanium, and copper react uncommonly well to fiber laser handling, coming about in high-contrast marks that stand up to erosion and wear.

Precision and Speed Advantages

Modern fiber laser frameworks accomplish stamping speeds up to 7000mm/s whereas keeping up tiny exactness. This combination of speed and precision altogether beats conventional etching strategies, diminishing generation time while improving stamp quality. The non-contact nature of laser checking kills device wear and mechanical stretch on fragile components.

Thermal Management Benefits

Fiber lasers create negligible heat-affected zones compared to other laser sorts, protecting the metallurgical properties of stamped components. This characteristic demonstrates basic for aviation and car applications where fabric keenness specifically impacts security and execution. The exact warm control avoids distorting, discoloration, or basic shortcomings in basic metal parts.

Applications of Fiber Laser Marking Machines in Metal Industries

Industrial applications for fiber laser marking and metal laser marking machines span multiple sectors, each presenting unique requirements and challenges. Understanding these applications helps manufacturers select appropriate marking solutions for their specific needs.

Automotive and Aerospace Component Marking

For lasting motor, transmission, and safety-critical get together distinguishing proof, automakers utilize fiber laser labeling. Turbine components, auxiliary parts, and route frameworks in aviation applications must be altogether more exact to meet tight administrative criteria. Fiber laser markings hold their perseverance at high temperatures, vibration, and chemical exposure.

Electronics and Consumer Device Manufacturing

Fiber laser marking's ultra-fine markings on circuit boards, semiconductor packages, and mobile device components serve the electronics sector. These applications need static-safe, non-invasive marking procedures that provide legible identifying codes without electrical interference. Consumer electronics makers like the technology's versatility for practical and aesthetic branding.

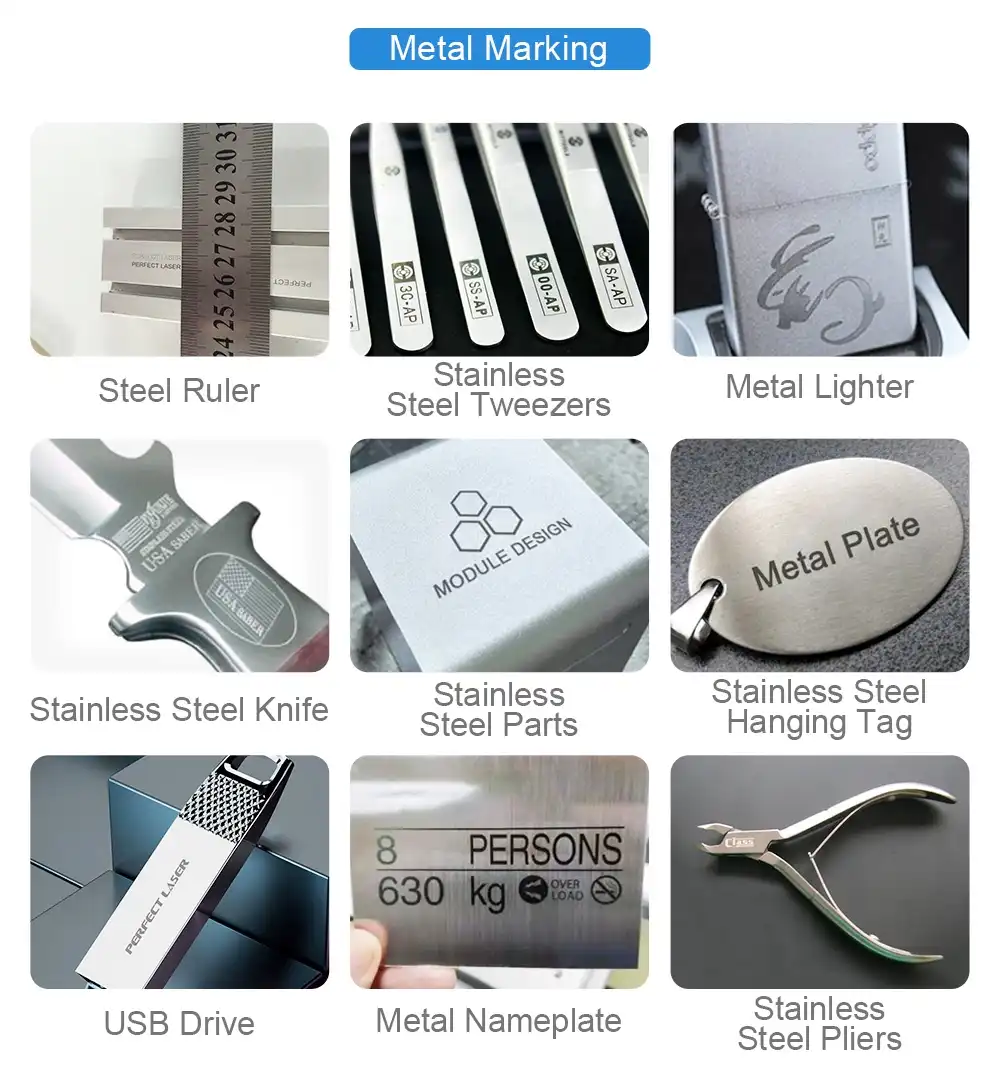

Industrial Hardware and Precision Tools

Precision gear, cutting instruments, and development equipment producers utilize fiber laser stamping for brand distinguishing proof and determination stamping. The strategy engraves solidified steel surfaces with high-contrast markings for item perceivability. Serial numbers, generation dates, and quality certification markings may be custom-marked.

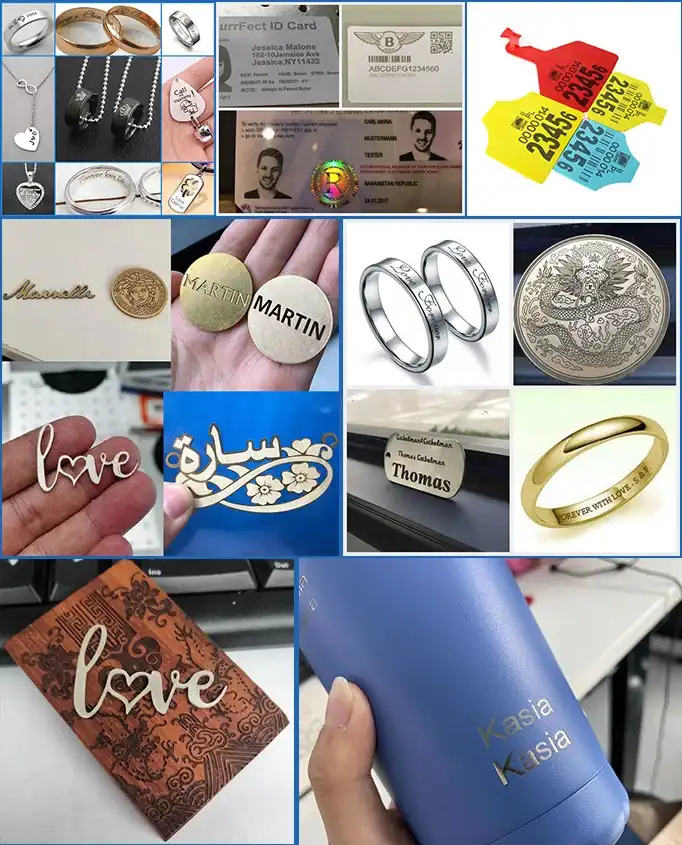

Luxury Goods and Personalization

Fiber laser checking is utilized for customization and brand recognizable proof by jewelry, watches, and extravagance adornment creators. The strategy imprints valuable metals richly and accurately without influencing surface cleanliness. Laser-marked distinguishing codes are lasting and tamper-evident, making them valuable for anti-counterfeiting.

Choosing the Right Fiber Laser Marking Machine for Your Metal Parts

Selecting an optimal laser marking system requires careful consideration of production requirements, part characteristics, and operational constraints. Perfect Laser offers comprehensive solutions addressing diverse industrial needs through innovative design approaches.

Machine Configuration Options

Perfect Laser provides multiple configuration options to match specific production environments. Here are the core machine types available:

Space-efficient desktop and versatile adaptations for littler generation settings and model advancement keep up stamping quality. Laser stamping innovation is reasonable for endeavors utilizing mini-type gadgets. Movable working statures permit lifting-type combinations for diverse portion sizes and complicated shapes. Full-closed plans protect administrators and the environment all through ceaseless operation.

These versatile configurations enable manufacturers to optimize their marking processes while maintaining flexibility for future expansion or application changes.

Advanced Technology Features

Modern fiber laser frameworks consolidate modern features, upgrading operational proficiency and checking capabilities. Rotary-type fiber laser etchers handle round, hollow, and bent components naturally, moving forward throughput while guaranteeing a reliable stamp situation. 3D energetic center moving working tables suit complex geometries and multi-level checking necessities without manual repositioning.

Power and Precision Specifications

Power yield determination depends on fabric thickness, checking depth requirements, and generation speed desires. High-power units exceed expectations in overwhelming mechanical applications requiring profound etching, whereas lower-power frameworks give fabulous results for surface checking and fine detail work. Determination capabilities decide the least include the estimate achievable, affecting stamp neatness and tasteful quality.

Maintenance, Safety, and Operational Best Practices

Proper maintenance and safety protocols maximize equipment performance while protecting personnel and ensuring consistent laser marking on stainless steel quality. Establishing comprehensive operational procedures supports long-term productivity and equipment reliability.

Preventive Maintenance Requirements

Fiber laser frameworks require negligible upkeep compared to conventional stamping gear. Normal cleaning of optical components keeps up pillar quality and anticipates control degradation. Discuss cooling frameworks require intermittent channel substitution and wind current confirmation to guarantee warm administration adequacy. Program upgrades and calibration checks keep up checking precision and framework compatibility with advancing generation requirements.

Safety Protocols and Training

Laser security guidelines order particular defensive gear and operational strategies. Certified security eyewear secures against scattered laser radiation, whereas legitimate ventilation evacuates any checking byproducts. A comprehensive administrator prepares and covers crisis methods, security interlocks, and legitimate dealing with strategies. Natural observing guarantees working environment compliance with word related wellbeing standards.

Performance Optimization Strategies

Optimizing laser stamping parameters for particular metal sorts and applications maximizes proficiency and quality. Parameter advancement includes altering control levels, beat frequencies, and stamping speeds to accomplish craved comes about. Normal execution checking distinguishes openings for change and avoids quality degradation over time.

Why Fiber Laser Marking Is the Preferred Choice for Metal Part Procurement?

B2B procurement professionals increasingly specify fiber laser marking systems based on proven performance advantages and long-term value proposition. The technology addresses critical business requirements while supporting operational excellence across diverse manufacturing environments.

Traceability and Compliance Benefits

Permanent laser marking enables complete supply chain traceability through tamper-proof identification codes. Automotive and aerospace industries require such capabilities for regulatory compliance and quality assurance programs. The durability of laser marks ensures readability throughout product lifecycles, supporting warranty claims and maintenance scheduling.

Return on Investment Considerations

While fiber laser systems represent significant capital investments, they deliver substantial operational savings through reduced consumables, minimal maintenance requirements, and improved throughput. The elimination of marking consumables like inks, labels, or engraving tools reduces ongoing operational costs. Higher marking speeds increase production capacity without additional labor requirements.

Customization and Flexibility Advantages

Modern fiber laser systems adapt to changing production requirements through software-based parameter control and flexible fixturing options. Variable data marking capabilities support mass customization and personalization trends. Integration with existing production lines occurs seamlessly through standard communication protocols and automation interfaces.

Perfect Laser: Your Trusted Partner for Advanced Marking Solutions

Perfect Laser Co., Ltd. has led industrial laser equipment production since 1995. Over 20 series and 300 laser equipment items for electronics, automotive, luxury goods, and precision manufacturing. Modern design makes our fiber laser marking equipment suitable for many industrial applications. Rotary-type fiber, UV purple light metal, compact, portable, desktop, lifting, multicolored, standby, and full-closed laser engravers are available. For complex marking applications, 3D dynamic focus shifting working table fiber laser etchers are unmatched. Perfect Laser systems are accurate, affordable, easy to use, and high-quality. Our steady 7000mm/s marking equipment include advanced air conditioning and reliable laser sources. The 2-year laser source guarantee reflects our confidence in product reliability and customer satisfaction.

Conclusion

Fiber laser marking technology represents the optimal solution for metal part identification across manufacturing industries. The combination of precision, speed, durability, and versatility makes these systems indispensable for modern production environments. Perfect Laser's comprehensive range of fiber laser marking machines addresses diverse industrial requirements through innovative design and proven performance. Our commitment to quality, supported by international certifications and extensive R&D capabilities, ensures customers receive reliable solutions backed by comprehensive support services. The technology's ability to enhance traceability, reduce operational costs, and improve production efficiency makes fiber laser marking the preferred choice for forward-thinking manufacturers seeking competitive advantages in today's demanding marketplace.

Frequently Asked Questions

Q1: Can fiber laser marking machines mark all types of metals effectively?

A: Yes, fiber laser marking machines excel at marking both ferrous and non-ferrous metals including stainless steel, aluminum, copper, titanium, and various alloys. The 1064-nanometer wavelength provides optimal absorption characteristics across different metal types, producing high-contrast, permanent marks suitable for industrial applications.

Q2: How does the cost of fiber laser marking compare to traditional engraving methods?

A: While fiber laser systems require higher initial investment, they offer superior long-term value through faster processing speeds, eliminated consumables, reduced maintenance requirements, and improved precision. The technology typically achieves payback within 12-24 months through operational savings and increased productivity.

Q3: What safety measures are essential when operating fiber laser marking equipment?

A: Essential safety measures include certified laser safety eyewear, adequate ventilation systems, comprehensive operator training, and adherence to laser safety standards. Proper installation of safety interlocks and emergency stop systems ensures operator protection while maintaining productive operation.

Partner with Perfect Laser for Superior Marking Solutions

Ready to transform your metal parts marking process with industry-leading technology? Perfect Laser offers comprehensive fiber laser marking machine solutions designed specifically for your manufacturing requirements. Our expert team provides complete support from initial consultation through installation, training, and ongoing service. With CE, TUV, and SGS certifications, plus a 2-year warranty on laser sources, you can trust Perfect Laser for reliable, high-performance marking solutions. Whether you need a fiber laser marking machine supplier for standard applications or custom solutions for specialized requirements, our global experience and technical expertise ensure optimal results. Contact us at [email protected] to discuss your specific needs and receive a detailed proposal tailored to your production goals.

References

1. Industrial Laser Solutions Magazine. "Advances in Fiber Laser Technology for Metal Marking Applications." 2023 Annual Review.

2. American Society for Testing and Materials. "Standard Guide for Laser Marking of Metals." ASTM F2038-22 Standard Specification.

3. Laser Institute of America. "Laser Safety Guide for Manufacturing Applications." LIA Safety Publication Series, 2023.

4. International Organization for Standardization. "Lasers and Laser-Related Equipment - Test Methods for Laser Beam Widths." ISO 11146 Standard.

5. Manufacturing Engineering Society. "Comparative Analysis of Metal Marking Technologies in Industrial Applications." Journal of Manufacturing Processes, 2023.

6. Aerospace Industries Association. "Traceability Requirements for Aircraft Component Marking." AIA Standards and Publications Committee Report, 2023.

第一张审核员说包含其他公司不能用_1755049724891.webp)