What is the Difference Between Fiber, CO2, and UV Laser Wavelengths?

To make an informed decision about which laser technology to adopt, it's essential to understand the fundamental differences between Fiber, CO₂, and UV lasers. These differences primarily stem from their respective wavelengths and how they interact with various materials.

Fiber Laser Wavelength Characteristics

Fiber lasers operate in the near-infrared spectrum, typically around 1064 nanometers. This wavelength is highly absorbed by metals, making fiber laser machines exceptionally efficient for metal cutting and engraving applications. The short wavelength allows for a smaller focal spot, resulting in higher precision and faster processing speeds.

CO₂ Laser Wavelength Properties

CO₂ lasers emit light in the far-infrared spectrum, usually at 10,600 nanometers. This longer wavelength is well-suited for processing organic materials such as wood, leather, and certain plastics. CO₂ lasers are known for their versatility and ability to produce high-quality cuts on non-metallic materials.

UV Laser Wavelength Characteristics

UV lasers operate at much shorter wavelengths, typically in the range of 355 to 266 nanometers. These wavelengths are highly energetic and can break molecular bonds in materials, making UV lasers ideal for micro-machining, fine engraving, and processing of heat-sensitive materials.

Metal Cutting and Marking: Which Laser Type is Most Efficient?

When it comes to metal processing, efficiency is paramount. Let's explore how each laser type performs in metal cutting and marking applications.

Fiber Laser Performance in Metal Processing

Fiber lasers excel in metal cutting and marking due to their high absorption rate in metallic materials. They offer superior speed, precision, and energy efficiency compared to other laser types when working with metals. Fiber laser cutting machine manufacturers have optimized these systems for a wide range of metal thicknesses, from thin sheets to thick plates.

CO₂ Laser Capabilities for Metal Work

While CO₂ lasers can cut and mark metals, they are generally less efficient than fiber lasers for these applications. The longer wavelength of CO₂ lasers results in more heat generation and wider kerf widths, which can lead to reduced precision and slower processing speeds when working with metals.

UV Laser Applications in Metal Industries

UV lasers are not typically used for heavy-duty metal cutting but excel in specialized metal marking and micro-machining tasks. Their short wavelength allows for extremely fine detail work and the ability to process thin metal foils without thermal damage.

How to Choose Based on Your Material and Desired Effect

Selecting the right laser technology depends on the specific materials you work with and the effects you aim to achieve. Let's break down the selection process based on common industrial applications.

Selecting Lasers for Metalwork

For businesses primarily focused on metal fabrication, fiber lasers are often the optimal choice. They offer unparalleled speed and precision in cutting, welding, and marking a wide range of metals, including steel, aluminum, and copper. Fiber laser cutting machine manufacturers provide systems capable of handling various metal thicknesses and compositions.

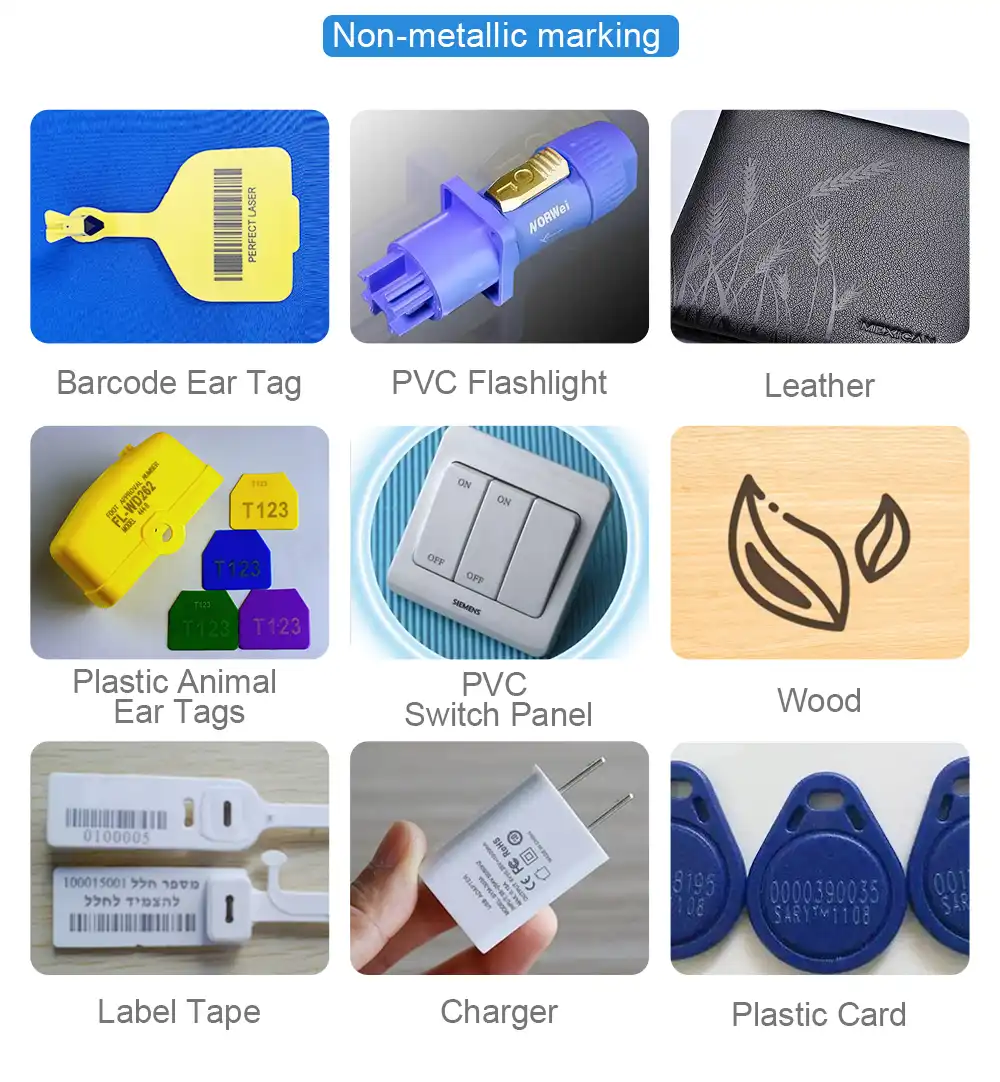

Choosing Lasers for Non-Metallic Materials

When working with materials such as wood, acrylic, or textiles, CO₂ lasers typically provide the best results. Their longer wavelength is ideal for cutting and engraving these materials with minimal charring and high-quality edge finishes.

Laser Selection for Precision Electronics

For industries involved in electronics manufacturing or micro-machining, UV lasers offer the precision required for delicate operations. They can create extremely fine features without thermal damage, making them ideal for PCB drilling, flex circuit processing, and semiconductor applications.

Considerations for Mixed Material Processing

Some industries require the ability to process both metallic and non-metallic materials. In such cases, a hybrid approach may be necessary, potentially involving multiple laser systems or a versatile fiber laser setup with additional capabilities for non-metallic materials.

Conclusion

Choosing between Fiber, CO₂, and UV laser technologies is a critical decision that can significantly impact your industrial operations. By understanding the strengths and limitations of each laser type, you can make an informed choice that aligns with your specific material processing needs and production goals.

- Fiber lasers are optimal for metal cutting and marking, offering high speed and precision.

- CO₂ lasers excel in processing non-metallic materials like wood and acrylics.

- UV lasers are best suited for micro-machining and ultra-precise applications in electronics.

- Consider your primary materials, desired effects, and production requirements when selecting a laser system.

As technology continues to advance, fiber laser cutting machine manufacturers and other laser equipment providers are constantly improving their offerings. Stay informed about the latest developments in laser technology to ensure your business remains competitive and efficient in your industry.

FAQ

Q: Can a single laser system handle both metal and non-metal materials?

A: While some advanced fiber laser systems can process certain non-metallic materials, it's generally more effective to use specialized lasers for different material types. CO₂ lasers are better suited for non-metals, while fiber lasers excel with metals.

Q: How does the cost of operation compare between Fiber, CO₂, and UV lasers?

A: Fiber lasers typically have lower operating costs due to their energy efficiency and low maintenance requirements. CO₂ lasers may have higher consumable costs, while UV lasers often have the highest operational expenses due to their specialized components.

Q: What safety considerations are important when using industrial lasers?

A: All industrial lasers require strict safety protocols, including proper enclosures, ventilation systems, and personal protective equipment. Fiber and UV lasers pose additional risks due to their invisible beams, necessitating extra precautions and safety interlocks.

Find Your Perfect Laser Match – Take Our Quiz!

Ready to enhance your production capabilities with state-of-the-art laser technology? Perfect Laser offers a comprehensive range of laser solutions tailored to your industry needs. Our expert team can help you select the ideal laser system to boost your efficiency and product quality.

Don't let outdated technology hold your business back. Contact Perfect Laser today for a personalized consultation and discover how our advanced Fiber Laser Cutting Machine can transform your manufacturing process. Email us at [email protected] or visit our website to learn more about our industry-leading laser solutions.

References

- Johnson, A. (2022). "Advancements in Industrial Laser Technologies: A Comparative Analysis of Fiber, CO₂, and UV Systems." Journal of Laser Applications, 34(2), 022-037.

- Smith, B., et al. (2021). "Material Processing Efficiency: Fiber vs. CO₂ Lasers in Metal Fabrication." International Journal of Advanced Manufacturing Technology, 112(5-6), 1485-1497.

- Lee, C. H. (2023). "UV Laser Applications in Microelectronics: Current Trends and Future Prospects." Optics & Laser Technology, 158, 108757.

- Brown, D. R. (2022). "Laser Selection Guide for Industrial Manufacturing: Matching Wavelengths to Materials." Industrial Laser Solutions, 37(3), 15-22.

第一张审核员说包含其他公司不能用_1755049724891.webp)