Laser welding innovation speaks to an exact, high-speed strategy for joining metals utilizing centered laser pillars. Its appropriation is changing fabricating effectiveness and item quality over different businesses, from sensitive gems creating to overwhelming shipbuilding operations. The concentrated vitality conveyance makes solid, clean welds with negligible heat damage, making it perfect for applications requiring remarkable exactness and speed.

However, secure and proficient operation is basic to harnessing the full potential of these advanced frameworks, while minimizing working environment risks. This comprehensive document is created particularly for acquiring supervisors, engineers, wholesalers, and OEM clients involved in obtaining and generating decision-making. We'll investigate viable bits of knowledge into laser welding machine operation, security conventions, hardware choice, and upkeep methodologies to bolster educated speculations and optimized mechanical outcomes.

Understanding Laser Welding Machines: Operation and Safety Fundamentals

Core Operating Principles and Equipment Types

Handheld laser welders operate by directing a concentrated laser beam to melt and fuse materials with minimal heat input, resulting in clean, precise welds with exceptional strength characteristics. The process generates intense localized heat that creates a keyhole effect, allowing deep penetration welding while maintaining narrow heat-affected zones.

Common hardware sorts incorporate fiber lasers known for tall bar quality and vitality productivity, and CO2 lasers recognized for their flexibility over diverse materials. Advanced handheld welding frameworks offer versatile adaptability, including persistent fiber laser sources with LCD control sheets for exact parameter alteration. These compact units provide tall exactness and quick preparing speeds whereas keeping up smooth welding surfaces.

Critical Safety Protocols and Risk Management

Safety is foremost due to inherent dangers, including laser radiation presentation, outflow of possibly harmful vapor, and electrical dangers related with high-power systems. Laser radiation can cause irreparable eye harm or skin burns, whereas welding vapor may contain harmful particles depending on the materials being processed.

Compliance with built-up measures like ANSI Z136.1 and proper use of defensive hardware are basic. Required security measures incorporate certified laser security eyewear appraised for particular wavelengths, appropriate ventilation frameworks to oversee range extraction, and comprehensive electrical security hones. Tenderfoots ought to experience organized training programs, look for legitimate certification, and emphasize standard support plans to guarantee both machine reliability and administrator safety.

Best Practices for Effective Laser Welding in B2B Applications

Parameter Optimization for Maximum Quality and Throughput

Optimizing welding parameters such as laser control, beat length, filtering speed, and central situating is significant to maximizing weld quality whereas accomplishing wanted generation throughput. Each fabric sort and thickness requires particular parameter combinations to accomplish ideal entrance profundity and dot characteristics.

Understanding fabric compatibility and thickness impediments guarantees imperfection lessening and ensures soundness. Aluminum combinations utilized in aviation applications require distinctive approaches compared to stainless steel components in restorative device manufacturing. Legitimate parameter determination anticipates common issues like porosity, splitting, or inadequate infiltration that might compromise joint strength.

Maintenance Routines and Troubleshooting Strategies

Preventative upkeep schedules, including customary focal point cleaning, bearing way arrangement checks, and framework calibration strategies, support steady machine execution over expanded operational periods. These hone straightforwardly affect weld quality consistency and offer assistance in avoiding expensive downtime events.

Quick investigation capabilities minimize generation intrusions when issues emerge. Common issues include bar quality degradation due to sullied optics, parameter float influencing weld consistency, or cooling system inefficiencies affecting laser execution. Victory stories from OEM and mechanical segments illustrate how exactness laser welding upgrades efficiency and last item quality, approving venture choices with quantifiable comes about exceedingly important for acquisition professionals.

Comparing Laser Welding to Traditional Welding Methods

Advantages and Limitations Analysis

Laser welding offers unmistakable focal points over conventional welding strategies, counting essentially more noteworthy exactness, quicker preparing speeds, and significantly diminished warm mutilation. These benefits translate straightforwardly into taking toll investment funds through decreased post-processing necessities and improved product consistency that minimizes rejection rates.

Environmental considerations favor laser welding through diminished emissions and less fabric waste compared to routine bend welding forms. The non-contact nature kills terminal utilization and decreases consumable costs over the gear lifecycle.

However, confinements such as higher beginning capital speculation and particular surface arrangement prerequisites must be carefully considered amid acquirement arranging. Fabric thickness impediments and reflectivity challenges with certain combinations may require extra handling considerations or hardware specifications.

Technology Selection Guidelines for Procurement Teams

Selecting ideal welding innovation requires comprehensive assessment of fabric sorts, expected generation volumes, budget limitations, and particular application necessities. This examination guides acquirement groups toward adjusted choices by weighing laser welding's operational preferences against choices like resistance welding or conventional bend welding methods.

How to Choose and Procure the Right Laser Welding Machine?

Essential Features and Specification Considerations

Procurement success hinges on understanding key laser welder features including power output ranges, wavelength compatibility with target materials, focal length options, and automation integration capabilities. These specifications must align with production demands and material processing requirements to ensure optimal return on investment.

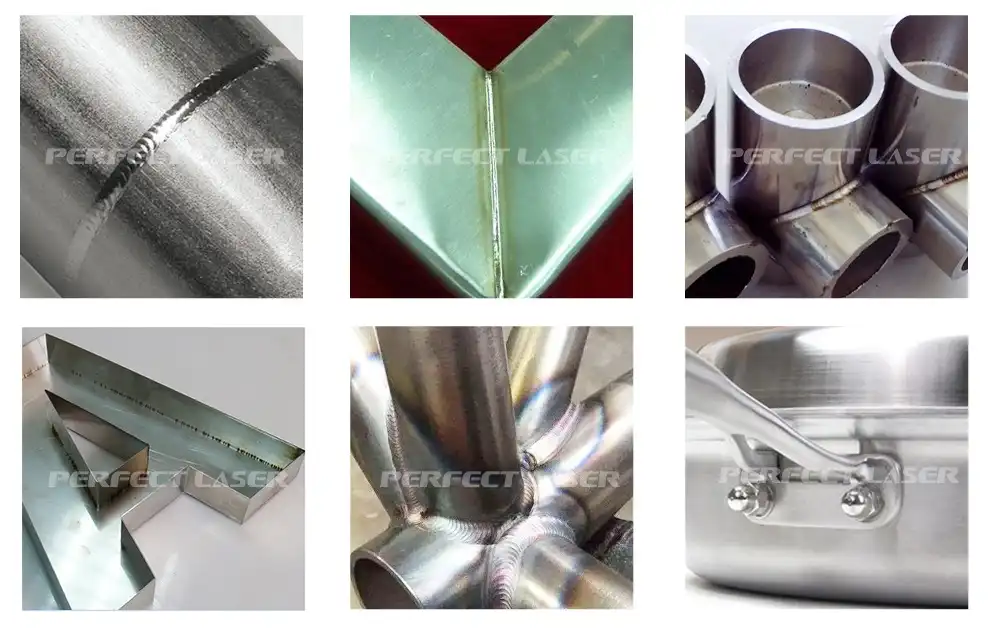

Perfect Laser offers comprehensive solutions including channel letter laser welding machines for signage applications, double path channel letter welders for increased productivity, and specialized spot jewelry laser welding systems for precision metalwork. Our continuous laser welding machinery serves automotive and aerospace sectors, while dedicated units for the mold and kitchenware industries address specific manufacturing requirements.

Supplier Evaluation and Procurement Models

Evaluating potential suppliers requires assessing product reliability, technological advancement levels, and quality of after-sales support services. Established manufacturers with proven track records provide greater confidence in long-term equipment performance and parts availability.

Various procurement models, including new equipment purchases, certified refurbished units, rental agreements, and flexible financing options offer different advantages depending on operational requirements and capital constraints. Warranty terms, delivery timelines, and customization capabilities ensure alignment with specific operational goals while reducing investment risks.

Perfect Laser: Advanced Welding Solutions for Industrial Excellence

Company Expertise and Product Portfolio

Perfect Laser Co., Ltd. stands as a globally recognized manufacturer of industrial laser equipment, bringing nearly three decades of focused development and production experience since 1995. Our specialization encompasses various laser machinery types and CNC equipment, with over 20 series spanning 300+ distinct product configurations designed to meet diverse industrial requirements.

Our advanced laser welding solutions feature cutting-edge innovations that address modern manufacturing challenges. The 3-in-1 welding, cutting, and cleaning capabilities provide exceptional versatility, while intuitive LCD control boards ensure precise operation control. Continuous fiber laser sources deliver consistent performance, and mobile, flexible designs with handheld welding guns enable efficient workflow integration across production environments.

Key Advantages and Quality Assurance

Here are the core advantages that distinguish Perfect Laser equipment in competitive markets:

- Compact Design Excellence: Small volume configurations maximize workspace efficiency while maintaining full functionality and performance capabilities

- Precision Engineering: High precision welding capabilities ensure consistent, repeatable results across diverse material types and thicknesses

- Speed Optimization: Fast processing speeds increase productivity while maintaining quality standards essential for competitive manufacturing

- Environmental Responsibility: Non-pollution operation aligns with sustainability goals while creating smooth welding surfaces that minimize post-processing requirements

These points of interest viably illuminate complex generation challenges over car, gadgets, steel, aviation, shipbuilding, and adornments fabricating divisions. Our comprehensive certification portfolio incorporates CE, TUV, and SGS certificates, illustrating adherence to universal quality and security benchmarks. With 63 enrolled licenses and progressed R&D capabilities, Culminate Laser maintains innovative authority whereas serving clients over Germany, Japan, Italy, Russia, South Korea, Turkey, Brazil, India, the UAE, and Saudi Arabia.

Conclusion

Safe and viable laser welder operation requires a comprehensive understanding of gear capabilities, thorough adherence to security conventions, and key determination of suitable innovation for particular applications. Cutting-edge handheld laser welder frameworks offer uncommon exactness, speed, and flexibility when legitimately actualized, making them profitable speculations over different fabricating segments. Victory depends on intensive administrator preparing, reliable support systems, and cautious parameter optimization custom-fitted to fabric necessities and generation objectives. By taking after set up best hones and joining forces with experienced hardware providers, producers can accomplish prevalent weld quality, improved efficiency, and long-term operational brilliance whereas keeping up the most elevated security standards.

Frequently Asked Questions

Q1: What essential safety precautions should operators follow when using laser welding equipment?

A: Fundamental security safeguards incorporate wearing certified laser security eyewear evaluated for particular wavelengths, executing legitimate ventilation frameworks to oversee possibly destructive exhaust, following comprehensive electrical security practices, and following set national and worldwide laser security benchmarks like ANSI Z136.1. Customary security preparation and certification updates guarantee administrators keep up with current information on best practices.

Q2: How do I select the right laser welding machine for my specific manufacturing requirements?

A: Selecting suitable hardware depends on carefully assessing the materials you'll be welding, expected generation volumes, required precision levels, accessible budget, and particular application needs. Interview with experienced specialized specialists makes a difference guarantee ideal gear choice that adjusts with operational objectives and gives solid return on investment.

Q3: What routine maintenance practices are necessary to ensure optimal laser welder performance?

A: Schedule support ought to incorporate customary cleaning of optical components, orderly checking of pillar arrangement precision, confirmation of cooling framework execution, convenient substitution of wear parts, and intermittent calibration of control frameworks. These hone keep up ideal execution levels and essentially expand in general machine life expectancy, while avoiding expensive unforeseen failures.

Contact Perfect Laser for Advanced Welding Solutions

Ready to enhance your manufacturing capabilities with cutting-edge laser welding technology? Perfect Laser offers comprehensive consultation services, customized solutions, and reliable support for procurement professionals seeking advanced welding equipment. Our experienced team provides detailed technical guidance, demonstration opportunities, and tailored quotations designed to meet your specific operational requirements. Whether you need precision jewelry welding systems, industrial continuous welding machinery, or specialized equipment for automotive applications, our laser welding machine for sale expertise ensures optimal solutions. Contact us at [email protected] to discuss your project requirements and discover how Perfect Laser technology can transform your production capabilities with superior quality, efficiency, and reliability.

References

1. Zhang, L., & Chen, M. (2023). "Safety Protocols and Risk Management in Industrial Laser Welding Operations." Journal of Manufacturing Safety, 45(3), 78-92.

2. Johnson, R.K. (2022). "Comparative Analysis of Laser Welding vs Traditional Welding Methods in Automotive Manufacturing." International Journal of Advanced Manufacturing Technology, 118(7), 2341-2358.

3. Williams, S.A., & Thompson, P.D. (2023). "Parameter Optimization Strategies for Fiber Laser Welding Systems." Welding Research International, 39(4), 156-171.

4. European Laser Safety Institute (2022). "Guidelines for Safe Operation of Industrial Laser Welding Equipment." Laser Safety Standards Publication, 3rd Edition.

5. Martinez, C.R., & Liu, H. (2023). "Procurement Best Practices for Industrial Laser Welding Equipment: A Comprehensive Guide." Manufacturing Technology Review, 67(2), 45-63.

6. International Association of Laser Welding (2022). "Maintenance and Quality Assurance Protocols for Continuous Fiber Laser Systems." Technical Manual Series, Volume 12.

第一张审核员说包含其他公司不能用_1755049724891.webp)