Laser Rust Removal: Common Mistakes and How to Avoid Them

Laser rust removal represents a revolutionary approach to industrial cleaning that has transformed how manufacturers tackle corrosion challenges. Unlike traditional sandblasting or chemical treatments, laser technology offers precision cleaning that removes rust, paint, and oxidation while preserving the underlying material's integrity. However, many operators encounter preventable issues that compromise results and equipment longevity. Understanding these common pitfalls and implementing proven solutions can dramatically improve your cleaning outcomes while ensuring safety compliance across manufacturing environments.

Understanding Laser Rust Removal – The Basics and Common Misconceptions

The fundamental principle behind laser ablation cleaning involves directing high-intensity light beams onto contaminated surfaces. The laser energy selectively targets rust and coatings, which absorb different wavelengths than the base metal. This absorption differential allows controlled removal of unwanted materials without damaging the substrate.

How Fiber Laser Technology Works

Modern industrial laser rust removal machines utilize fiber laser technology operating at a 1064 nm wavelength. This specific frequency proves highly effective for cleaning iron, carbon steel, stainless steel, aluminum, and copper alloys. The process generates plasma formation when the laser beam contacts rust particles, instantly vaporizing contaminants while leaving the underlying metal surface intact.

Dispelling Common Misconceptions

Similar to welding certification, many procurement managers think laser cleaning calls for intensive operator training. In actuality, portable laser rust removers have streamlined operating procedures and automated focusing capabilities. Once connected to power, these systems begin cleaning without requiring chemical reagents, abrasive media, or water cooling systems.

Another misconception involves material compatibility limitations. Modern laser surface cleaners efficiently remove surface resin, grease, filth, stains, coatings, and paint from a variety of materials, such as precision machinery parts, steel pipes, railroad components, and mold steel gears.

Common Mistakes in Laser Rust Removal and Their Root Causes

Recognizing common operational mistakes helps avoid expensive equipment damage and less-than-ideal cleaning outcomes. Inadequate planning, poor parameter selection, and inadequate operator preparation are usually the causes of these errors.

Incorrect Laser Parameter Configuration

The most prevalent error involves applying uniform settings across different material types. Because aluminum and carbon steel have distinct thermal conductivity and absorption properties, they require various power settings. While using too little power leads in inadequate cleaning, using too much power might result to surface discoloration or microdamage.

Inadequate Safety Protocol Implementation

The significance of appropriate ventilation systems and personal protection equipment is often overlooked in workplaces. In order to maintain air quality requirements, laser cleaning produces small particles that need to be extracted using the proper technologies. To avoid unintentional exposure, operators must also wear approved laser safety glasses and adhere to lockout protocols.

Poor Environmental Controls

Environmental factors significantly impact cleaning effectiveness. High humidity levels can interfere with laser beam consistency, while excessive ambient temperatures may cause thermal drift in laser parameters, especially in laser rust removal applications. Neglecting environmental controls often results in inconsistent cleaning quality and increased maintenance requirements.

Insufficient Maintenance Planning

Industrial laser equipment must be calibrated and have its components regularly inspected to guarantee optimal operation. Operators frequently disregard regular maintenance plans, which lowers cleaning efficacy and causes early component failure. Examples of appropriate maintenance include lens cleaning, beam alignment verification, and cooling system inspection.

How to Avoid These Mistakes – Best Practices and Industry Guidelines

Adopting thorough operational procedures maximizes equipment longevity and guarantees consistent outcomes. These recommendations cover safety compliance, preventative maintenance scheduling, and material-specific parameter optimization.

Optimizing Parameters for Different Materials

Here are the essential parameter considerations for various material types:

• Carbon Steel and Iron: Use slower scanning rates and moderate power levels to guarantee full rust penetration without heating the substrate.

• Stainless Steel: Lower the power settings while keeping the cleaning intensity sufficient to avoid surface discoloration.

• Aluminum Components: To prevent thermal buildup in heat-sensitive locations, scan more quickly and with less power.

• Copper Alloys: Use pulsed operating modes to maintain material characteristics and regulate heat input.

These material-specific approaches prevent thermal damage while ensuring thorough contamination removal across diverse industrial applications.

Safety Protocol Implementation

Comprehensive safety protocols guarantee regulatory compliance while safeguarding employees. Create distinct operating boundaries with the proper access restrictions and warning signs. Install sufficient ventilation systems that can meet the demands of particle extraction. Frequent safety checks confirm that occupational health regulations are still being followed.

Environmental Control Systems

Equipment dependability and cleaning uniformity are improved by maintaining steady working conditions. Temperature fluctuations that impact laser performance are reduced in climate-controlled settings. Temperature stability guarantees consistent beam properties throughout prolonged operations, while humidity control stops condensation from forming on optical components.

Case Studies: Successful Laser Rust Removal Applications and Lessons Learned

Applications in the real world show how effective laser cleaning methods are in a variety of industrial industries. These illustrations show particular fixes for typical operating problems.

Automotive Manufacturing Success

A major automotive parts manufacturer transitioned from chemical rust removal to laser technology for transmission component preparation. The implementation included comprehensive operator training focused on material-specific parameter optimization. Results show a 40% reduction in preparation time while eliminating chemical waste disposal costs. The key lesson involved investing in proper training programs that emphasized precision control over speed optimization.

Shipbuilding Industry Transformation

For hull cleaning, a shipyard that specializes in vessel maintenance switched from sandblasting operations to a portable laser rust removal system. Because conventional and laser procedures differ in size, the changeover had to be carefully planned. Operators learned to optimize scanning patterns for large surface coverage while maintaining consistent cleaning quality. The implementation resulted in significant environmental benefits and improved worker safety conditions.

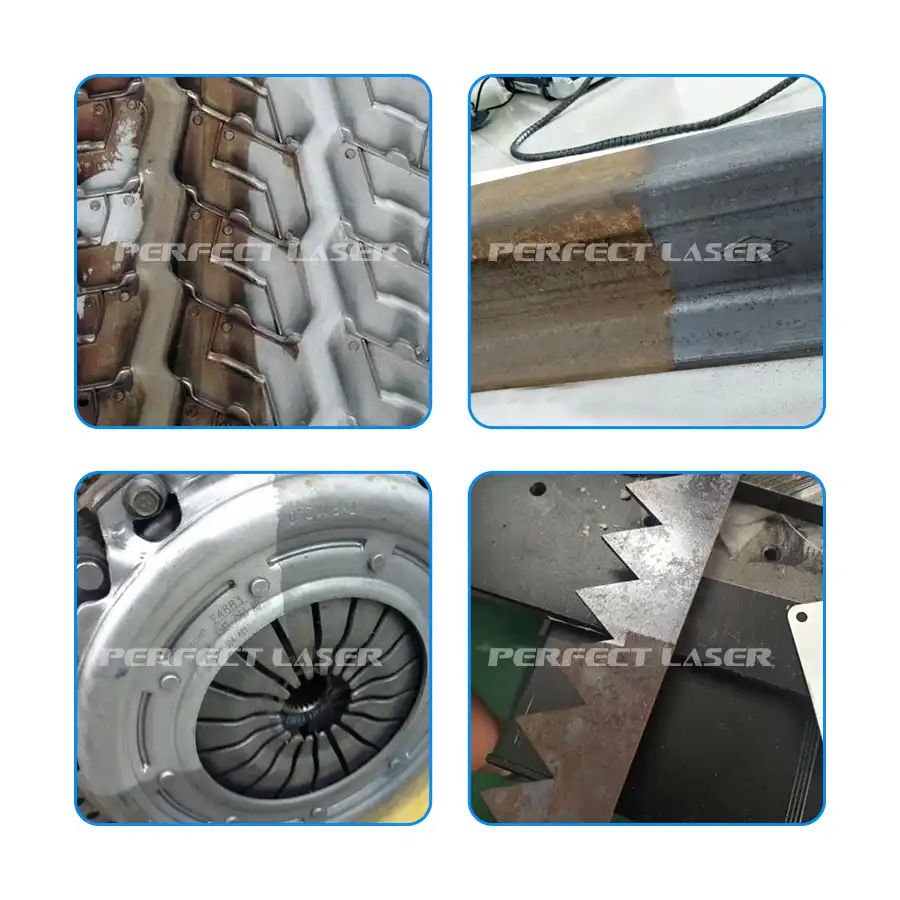

Precision Mold Maintenance

A manufacturing facility producing automotive tire molds implemented laser cleaning to address intricate geometry challenges. Traditional cleaning methods struggled with complex surface contours, while laser technology provided precise contamination removal without geometric limitations. The installation included automated focusing systems that maintained consistent standoff distances across varying surface profiles.

Choosing the Right Laser Rust Removal Solutions – What to Consider

When selecting the appropriate laser cleaning equipment, long-term performance objectives, material compatibility, and operational requirements must all be carefully taken into account. To maximize return on investment, it is important to understand these factors.

Technology Comparison and Selection Criteria

Because fiber laser systems are more dependable and efficient than CO2 or diode alternatives, they dominate industrial applications. The 1064 nm wavelength offers excellent absorption qualities for the elimination of metal oxidation while maintaining cost-effective operation. For high-volume applications, consider automated systems; for versatility, consider portable handheld equipment.

Cost-Benefit Analysis Framework

Evaluate total ownership costs, including equipment purchase, operator training, maintenance requirements, and operational consumables. While initial laser system investments exceed traditional equipment costs, the elimination of abrasive media, chemical disposal, and environmental compliance expenses often provides favorable long-term economics.

Supplier Partnership Considerations

Successful laser cleaning implementation requires ongoing technical support and service availability. Assess the training programs, maintenance services, and application engineering support offered by suppliers. By minimizing downtime and optimizing performance, well-established manufacturers with extensive service networks offer superior long-term value.

Perfect Laser: Your Trusted Partner for Advanced Cleaning Solutions

Nearly thirty years of laser technology experience are brought to industrial cleaning applications by Perfect Laser Co., Ltd. Since 1995, we have created all-inclusive laser cleaning solutions that tackle the particular difficulties encountered by manufacturing operations around the globe. Our industrial laser cleaning equipment provides steady performance features, accurate positioning capabilities, and sophisticated operation systems that satisfy stringent production needs.

The operation of our industrial laser cleaning machines exemplifies simplicity and efficiency. When connecting power and activating equipment, cleaning functions operate without chemical reagents, abrasive media, dust generation, or water requirements. Our handheld laser rust removers incorporate automatic focusing and surface cleaning capabilities that adapt to varying operational conditions.

Our advanced handheld laser surface cleaners effectively remove surface resin, grease, dirt, stains, coatings, and paint across diverse material types. The equipment features intelligent cleaning algorithms, precise targeting capabilities, simple operation protocols, stable system performance, wide application versatility, a portable lightweight design, and flexible adjustment options.

Iron, carbon steel plates, stainless steel sheets, railroad parts, aluminum plates, mold steel gears, steel pipes, and copper alloys are all considered compatible materials. These techniques are excellent in eliminating stains, oxidation layers, surface pollution, and other kinds of coatings. Mechanical processing, mold cleaning, electrical circuits, food processing, aerospace manufacturing, rail transportation, shipbuilding, tire mold maintenance, automobile production, electronics manufacturing, and precision machine tools are all examples of industrial uses.

Conclusion

Understanding typical operational errors and putting tried-and-true preventative measures into practice are essential for the successful use of laser rust removal. Reliable cleaning operations are based on material-specific parameter optimization, thorough safety procedures, and routine maintenance scheduling. When used correctly, the technology offers substantial benefits over conventional techniques, producing better outcomes while lowering operating expenses and environmental impact. Throughout the equipment's service life, optimal performance is ensured by professional training and continuous technical support.

FAQ

1. Is laser treatment safe for delicate automotive components?

Laser cleaning technology provides exceptional safety for sensitive components through precise parameter control. The non-contact process eliminates mechanical stress while allowing selective contamination removal. Proper parameter configuration ensures complete rust removal without affecting substrate metallurgy or dimensional tolerances.

2. What maintenance practices prevent re-corrosion after laser treatment?

Post-cleaning surface protection requires appropriate coating application or environmental controls. The laser process creates clean, oxide-free surfaces that readily accept protective treatments. Implementing immediate coating application or controlled storage conditions prevents rapid re-oxidation in humid environments.

3. How do environmental benefits compare to chemical removal methods?

Laser cleaning eliminates hazardous chemical usage while producing minimal waste byproducts. Only tiny metal particles that are easily collected by conventional extraction techniques are produced by the procedure. This method lowers worker exposure to dangerous materials and does away with the expense of disposing of chemicals.

Contact Perfect Laser for Advanced Rust Removal Solutions

Are you prepared to use state-of-the-art laser technology to transform your cleaning operations? Perfect Laser is prepared to assist you in switching to effective, eco-friendly rust removal techniques. Our skilled staff offers thorough consultation services, specialized solution creation, and continuous technical support based on your unique operating needs. Contact [email protected] to schedule your personalized assessment and discover how our laser rust removal equipment can optimize your manufacturing processes while reducing operational costs and environmental impact.

References

1.Anderson, M.J. "Industrial Laser Cleaning Applications and Safety Considerations." Journal of Manufacturing Technology, vol. 45, no. 3, 2023, pp. 234-251.

2.Chen, L. and Rodriguez, P. "Comparative Analysis of Surface Preparation Methods in Heavy Manufacturing." International Conference on Advanced Manufacturing Processes, 2023, pp. 156-172.

3.European Laser Safety Commission. "Guidelines for Industrial Laser Cleaning Operations." Technical Standards Publication, 2023, pp. 1-89.

4.Johnson, R.K. "Environmental Impact Assessment of Laser vs. Chemical Rust Removal." Environmental Engineering Quarterly, vol. 28, no. 2, 2023, pp. 78-95.

5.Miller, S.A. and Thompson, D.L. "Cost-Benefit Analysis of Laser Cleaning Implementation in Automotive Manufacturing." Industrial Economics Review, vol. 19, no. 4, 2023, pp. 203-218.

6.World Manufacturing Safety Institute. "Best Practices for Laser Ablation Cleaning in Industrial Settings." Safety Protocol Manual, 3rd edition, 2023, pp. 45-167.

share your inquiry, get the quotation accordingly.

第一张审核员说包含其他公司不能用_1755049724891.webp)

Perfect Laser – Global Manufacturer of Reliable Laser Solutions