What Is Laser Welding Used For in Industry?

In today's production environments, welding systems that can handle complex geometries, incompatible materials, and tight tolerances while maintaining consistent quality are crucial. Because of its unique combination of precise beam control and focused energy delivery, laser welding is a vital technology for competitive industrial processes. Industrial laser welding technology has transformed modern manufacturing by delivering unparalleled precision, efficiency, and reliability across diverse sectors. An industrial laser welding machine uses concentrated laser energy to join materials with exceptional accuracy, making it indispensable for applications ranging from automotive assembly to aerospace components. This advanced joining method creates strong, clean welds while minimizing heat-affected zones, enabling manufacturers to meet stringent quality requirements while improving production throughput and reducing operational costs. Because laser welding technology offers highly accurate, effective, and adaptable joining solutions, it has completely transformed industrial manufacturing. Its capacity to fulfill ever-tougher production and quality demands across a variety of sectors is reflected in its growing demand on a global scale. By providing clear insights into laser welding applications, benefits, and important considerations to take into account when choosing equipment, this handbook seeks to assist distributors, engineers, and procurement managers in making well-informed selections that are in line with technical specifications and corporate objectives.

Overview of Industrial Laser Welding and Its Applications

To produce robust, accurate welds, industrial laser welding combines sophisticated laser sources with exact beam control. In many applications, the method creates metallurgical linkages without the need for filler materials by using focused laser beams to heat and fuse materials at particular places. Manufacturers may solder sensitive components without causing damage to nearby areas because of this technology' exceptional control over heat input.

Core Technology Principles

Fiber lasers and CO2 lasers are the two primary technologies used in industrial applications. When welding reflective materials like copper and aluminum, fiber lasers offer superior beam quality and energy efficiency. Because CO2 lasers perform very well on thicker materials and non-metallic applications, they are helpful for some industrial demands.

The welding process can make use of both continuous wave (CW) and pulsed laser modes. While CW lasers provide continuous beams suitable for deep penetration welds and high-speed seam welding, pulsed lasers provide controlled energy bursts ideal for precision applications and heat-sensitive materials.

Key Industry Applications

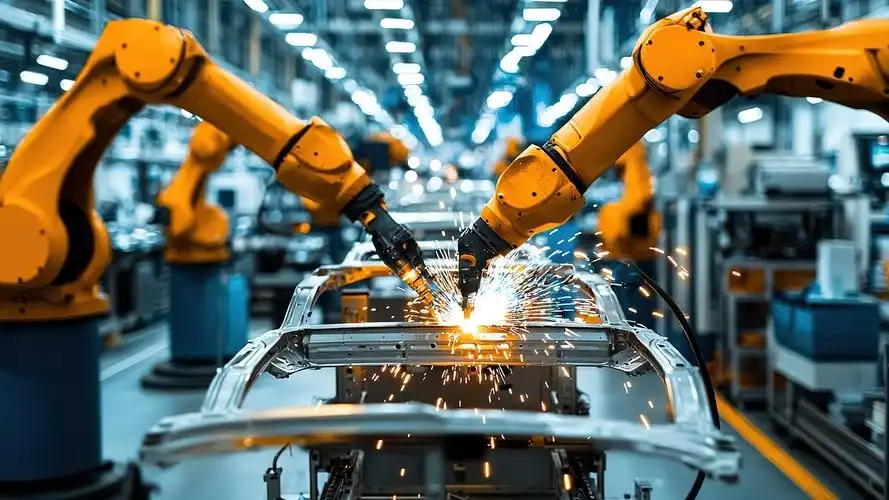

Industrial laser welding machines are used extensively in the automotive industry to combine lightweight aluminum components, produce robust body panel welds, and assemble vital engine components. Manufacturers can satisfy production volume needs while upholding structural integrity standards because of the technology's speed and accuracy.

The highest quality requirements are required for aerospace applications, where laser welding offers dependable connections in stainless steel parts, titanium alloys, and vital safety systems. For aviation parts that must endure harsh operating conditions, the procedure guarantees constant penetration and little deformation.

The micro-precision capabilities of laser welding are advantageous to the electronics and semiconductor sectors because they allow the connecting of small components without causing heat damage to delicate circuits. Excellent beam control and precise placement are necessary for this application in order to establish dependable connections in smaller devices.

Advantages of Industrial Laser Welding Over Traditional Welding Methods

By providing greater accuracy, quicker processing rates, and less thermal distortion, laser welding performs better than traditional techniques. Narrow heat-affected zones are produced by the concentrated laser beam, which lowers material stress and preserves component integrity. Components that would be difficult to combine using conventional arc welding techniques may be welded because of this accuracy.

Speed and Efficiency Benefits

Depending on the thickness of the material and the needs of the application, processing speeds can approach 100 inches per minute or more, far beyond those of traditional welding techniques. Improved production throughput and lower manufacturing costs are directly correlated with this speed advantage.

The remarkable repeatability of the technique eliminates the fluctuation frequently associated with human welding procedures, ensuring uniform weld quality over huge production runs. Automated laser welding systems can meet continuous production needs by maintaining exact settings during lengthy operations.

Material Versatility and Quality

A wide variety of materials, including incompatible metal combinations that pose difficulties for conventional welding techniques, may be welded using laser technology. The procedure reduces overall production time and costs by producing smooth, visually attractive weld surfaces that frequently require little post-processing.

Energy efficiency is another significant advantage, as laser systems transform electrical energy into welding heat more effectively than conventional methods. This efficiency reduces operating costs while advancing environmental sustainability goals, which are becoming increasingly important for modern businesses.

How to Choose the Right Industrial Laser Welding Machine for Your Business

A thorough assessment of several technical and commercial aspects is necessary when choosing the best laser welding technology. The range of materials and thicknesses that the system can efficiently process depends on laser power, which is a major factor. For heavy industrial use, power needs might range from several kilowatts to 200 watts for micro-welding applications.

Technical Specifications and Capabilities

Machine type selection between fiber and CO2 lasers depends on your specific material requirements and application needs. Fiber lasers offer superior performance for most metallic materials and provide excellent beam quality for precision applications. Certain thick material applications and certain non-metallic welding needs continue to benefit from CO2 lasers.

Long-term productivity and return on investment are greatly impacted by automation capabilities. Lights-out operation and reliable quality control are made possible by systems with sophisticated motion control, vision guiding, and process monitoring. Integration with existing production lines requires careful consideration of interface requirements and workflow optimization.

Cost of Ownership Considerations

Beyond the original equipment purchase, maintenance needs, anticipated equipment longevity, and post-purchase assistance are all included in the total cost of ownership. When properly maintained, high-quality laser systems may last for ten to fifteen years, making them wise long-term investments for expanding industrial operations.

Operating expenses are significantly impacted by energy efficiency, especially in high-volume manufacturing settings. By turning more than 30% of electrical energy input into effective laser output, modern fiber laser systems reach exceptional efficiency levels that much surpass the efficiency of earlier CO2 technology.

Safety, Maintenance, and Common Challenges in Laser Welding

Strict adherence to specified safety procedures and thorough operator training are necessary for the safe use of industrial laser welders. Because laser radiation poses significant risks to human skin and eyesight, regulated work settings and appropriate safety gear are required. Interlocks, beam confinement, and emergency stops are examples of safety systems that need to be properly maintained and checked on a regular basis.

Maintenance Requirements

Consistent performance and equipment lifetime are guaranteed by regular maintenance programs. Safety interlocks, cooling systems, and beam delivery components should all be inspected every day. Cleaning optical components and inspecting consumables like filters and protective glass are common weekly maintenance tasks.

Welding precision and quality uniformity are maintained by calibration methods. To guarantee that beam location and power delivery stay within predetermined tolerances, these operations should be carried out by competent specialists utilizing the proper measuring tools.

Troubleshooting Common Issues

Inadequate shielding gas flow or tainted materials are common causes of porosity in welds. Gas flow optimization and meticulous material preparation are necessary to solve this problem. Inconsistencies in weld penetration usually point to issues with focus location or power instability, necessitating system recalibration.

Rapid cooling rates or concentrations of material stress can cause cracks to emerge. These issues can be successfully resolved while upholding production requirements by changing joint designs, preheating materials, or adjusting welding conditions.

Industry Trends and Future Outlook of Laser Welding Technology

Technological Advancements

Smart manufacturing systems increasingly incorporate laser welding as a connected process element, sharing data with enterprise resource planning systems and quality management platforms. Predictive maintenance, process optimization, and thorough production tracking are made possible by this connection.

Beam shaping technology opens up new uses and improves process control by enabling precise control over energy distribution. These advancements expand the breadth of laser welding applications by enabling the welding of previously challenging material combinations and complex shapes.

Market Growth and Applications

The market is expanding due to expanding applications in the manufacturing of consumer electronics, medical devices, and renewable energy. The technology's capacity to combine various materials fosters innovative product designs and manufacturing techniques in a number of sectors.

Because laser welding uses less energy and produces less material waste than traditional joining techniques, it is becoming more and more popular when it comes to sustainability. Adoption decisions are influenced by legal requirements and company sustainability goals, both of which are in line with this environmental benefit.

Company Introduction and Our Laser Welding Solutions

Perfect Laser brings extensive expertise and a comprehensive portfolio of premium laser welding equipment designed to meet diverse industrial manufacturing needs. Since 1995, we have focused on developing and producing various types of laser machinery, earning recognition as a world-renowned manufacturer with over 300 equipment types across 20+ series.

Our Product Range

Our laser welding solutions include specialized equipment for multiple applications and industries. The channel letter laser welding machine provides precise joining for signage manufacturing, while our double-path channel letter welder increases production efficiency for high-volume operations. Continuous fiber laser sources and LCD control boards provide dependable performance in these systems.

For the creation of premium goods, spot jewelry laser welding equipment creates remarkably accurate, almost imperceptible seams on precious metals. High-speed seam welding for automotive, electronics, and aerospace applications is possible with our continuous laser welding equipment. Additionally, our laser welders for mold and kitchenware industries provide the durability and precision required for these demanding applications.

Advanced Features and Benefits

Our 3-in-1 welding, cutting, and cleaning devices combine several tasks onto small, portable platforms, offering remarkable adaptability. These portable welding gun systems offer quick processing rates, excellent precision, and small quantities. The smooth welding surfaces and non-polluting operation satisfy industry-wide quality standards.

Perfect Laser has obtained TUV and SGS certifications and upholds stringent quality requirements with CE certification. With 63 patents and several technological innovations that sustain world-class performance standards, our skilled R&D teams work out of two specialized facilities.

Conclusion

Industrial laser welding, enabled by the industrial laser welding machine, has established itself as an indispensable technology for modern manufacturing, offering unmatched precision, efficiency, and versatility across diverse applications. From automotive and aerospace manufacturing to electronics and luxury goods production, this technology enables manufacturers to meet increasingly demanding quality standards while improving productivity and reducing costs. The continuous evolution of laser welding systems, incorporating AI-driven automation and smart manufacturing integration, positions this technology at the forefront of Industry 4.0 initiatives. As manufacturers seek competitive advantages through advanced production capabilities, investing in quality laser welding equipment represents a strategic decision that supports long-term growth and operational excellence.

FAQ

1. What materials can be welded using industrial laser welding machines?

Industrial laser welding machines can join a wide variety of materials including, stainless steel, aluminum, titanium, carbon steel, copper, and various alloys. Additionally, the technology makes it possible to fuse disparate materials that would be difficult to do using conventional techniques. Depending on laser power and application needs, material thickness possibilities range from tiny foils under 0.1 mm to plates several millimeters thick.

2. How does laser welding compare to traditional welding methods in terms of cost?

Although laser welding systems need a larger initial equipment investment than conventional welding equipment, laser technology often has a lower total cost of ownership. Faster processing rates, fewer material waste, fewer post-processing needs, and lower energy use are some advantages. These elements usually lead to better return on investment and reduced per-part costs, especially in medium- to high-volume manufacturing settings.

3. What maintenance is required for laser welding equipment?

Daily optical component cleaning, weekly cooling system and protective window inspections, and recurring beam placement and power output calibrations are all part of routine maintenance. While more complicated operations call for expert professionals, most maintenance chores may be completed by trained operators. Equipment life may be increased to ten to fifteen years or longer with proper maintenance, which guarantees continuous performance.

Perfect Laser: Your Trusted Industrial Laser Welding Machine Supplier

Ready to transform your manufacturing capabilities with advanced laser welding technology? Perfect Laser offers comprehensive solutions tailored to your specific production requirements, from handheld systems for flexible operations to fully automated lines for high-volume manufacturing. Our experienced team provides personalized consultations, helping you select the optimal industrial laser welding machine supplier that aligns with your business objectives and technical specifications. Contact us today at [email protected] to discuss your welding challenges and discover how our proven technology can enhance your competitive advantage. We invite you to explore our complete product catalog and schedule a demonstration to experience the precision and efficiency of Perfect Laser welding systems firsthand.

References

1.Smith, J.A. "Advanced Laser Welding Technologies in Modern Manufacturing." Journal of Industrial Manufacturing, Vol. 45, No. 3, 2023, pp. 112-128.

2.Chen, L. and Rodriguez, M. "Comparative Analysis of Laser Welding vs. Traditional Joining Methods in Automotive Production." International Manufacturing Technology Review, 2024, pp. 67-89.

3.Williams, R.K. "Safety Protocols and Best Practices for Industrial Laser Welding Operations." Industrial Safety Quarterly, Vol. 29, No. 2, 2023, pp. 45-62.

4.Thompson, D.B. "Market Trends and Future Outlook for Laser Welding Technology." Manufacturing Technology Insights, 2024, pp. 23-41.

5.Anderson, P.L. "Cost-Benefit Analysis of Laser Welding Implementation in Medium-Scale Manufacturing." Production Economics Journal, Vol. 38, No. 1, 2023, pp. 156-174.

6.Kumar, S. and Davis, H.M. "Integration of AI and Machine Learning in Modern Laser Welding Systems." Advanced Manufacturing Technology, Vol. 52, No. 4, 2024, pp. 203-221.

share your inquiry, get the quotation accordingly.

第一张审核员说包含其他公司不能用_1755049724891.webp)

Perfect Laser – Global Manufacturer of Reliable Laser Solutions