The interaction of concentrated laser energy with transparent materials is the fundamental technology of 3D crystal laser engraving. The technology uses a 355 nm UV laser to create precise energy pulses that enter the glass or crystal and cause micro-explosions and localized heating at certain locations. The necessary three-dimensional picture is produced by the microscopic voids created by these micro-explosions.

3D Glass Pictures Created by a 3D Crystal Laser Engraving Machine

3D glass pictures created by a 3d crystal laser engraving machine represent a revolutionary breakthrough in precision manufacturing technology. These sophisticated devices utilize focused UV laser beams to create intricate three-dimensional images inside transparent materials like crystal and glass. Through precise control of laser energy, focus positioning, and movement trajectories, the 3d crystal laser engraving machine forms microscopic bubbles or controlled fractures within the material structure, resulting in stunning visual effects that appear suspended within the crystal itself.

Understanding 3D Crystal Laser Engraving Technology

The Step-by-Step Engraving Process

Digital design is the first step in the engraving process, when specialized software transforms 2D pictures into 3D coordinate data. After that, the 3D crystal laser engraving machine uses its galvanometer system to process this data at up to 150,000 points per minute. Each voxel is created with submicron accuracy when the UV laser passes through the material in exact patterns.

In order to maintain constant picture quality despite internal structural alterations, modern systems use dynamic focusing, which modifies the laser's focal point during the procedure. Intricate detail replication and material distortion are prevented by the non-contact process, which is not possible with traditional techniques.

Machine Types and Specifications

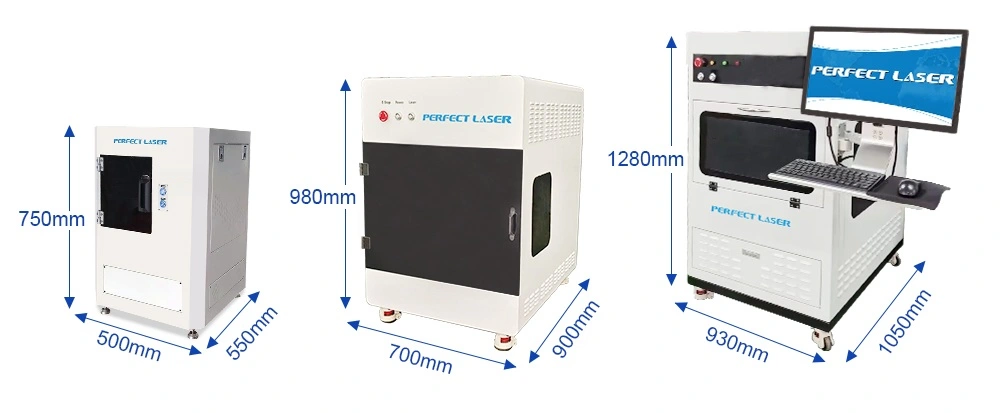

Modern 3D crystal laser engraving devices are available in a range of sizes to accommodate diverse commercial requirements. For jewelry workshops and boutique gift stores, small desktop versions with a 50x50mm working space and a weight of around 47 kg are ideal. These little devices are simple to use and transport, yet they provide professional-grade accuracy.

Larger working spaces for larger crystals and higher production volumes are provided by medium-sized industrial facilities. For reliable operation after prolonged usage, they have improved cooling systems and sophisticated beam stabilization. In high-volume industrial environments, large-scale machines with several laser sources and automated material handling enable continuous operation.

Compatible Materials and Design Considerations

Crystal is still the principal medium because of its superior optical clarity and structural consistency, even though 3d glass photo printing materials may be used with 3D crystal laser engraving machine technology. Excellent engraving results may be achieved with lead crystal, K9 crystal, and optical-grade glass. Although they have different visual qualities from conventional crystal, acrylic materials also show compatibility.

Understanding material properties and laser interaction characteristics is necessary for design optimization. High contrast and well-defined images yield better outcomes. The engraving program ensures excellent picture quality across various crystal compositions by automatically adjusting laser settings based on material type and desired depth.

Benefits and Applications of 3D Crystal Laser Engraving Machines

Beyond conventional surface engraving techniques, 3D crystal laser engraving machine technology offers significant business benefits. These systems are positioned as premium manufacturing solutions across several sectors because to their extraordinary longevity, fine detail replication, and excellent accuracy.

Enhanced Precision and Quality Standards

Through sophisticated galvanometer control and precise optics, modern 3D crystal laser engraving machines attain submicron-level accuracy, allowing for the remarkably clear replication of architectural elements, photographic details, and complex patterns. Tool wear and mechanical vibrations that are typical of conventional procedures are eliminated by the non-contact engraving process.

Permanent pictures that are impervious to fading, wear, and environmental damage are produced via laser engraving. Under typical circumstances, internal crystal engravings maintain their visual effect eternally, in contrast to surface treatments or applied graphics. Because of their endurance, crystal engravings are ideal for awards, commemorative objects, and high-end presents.

Industry Applications and Commercial Uses

3D crystal laser engraving equipment, which enable the rapid manufacturing of location-themed souvenirs showcasing monuments, architecture, or landscapes, are very beneficial to the tourist and souvenir businesses. On-site customized crystal goods can improve visitor experiences and open doors for premium pricing at tourist destinations.

Crystal engraving technology is used by photography studios and wedding businesses to provide one-of-a-kind portrait presents and mementos. In competitive marketplaces, studios may provide unique items and premium pricing by using 3D cameras to record and replicate three-dimensional images as crystal sculptures.

3D crystal engraving technology is used by gift shops and retail establishments to provide customized engraving for logos, images, and unique designs. These solutions are attractive to shops that want to increase their options and profitability due to the great profit potential of personalized crystal items.

Crystal engraving is used by hotels and galleries for recognition prizes, creative displays, and high-end business presents. Crystal engravings are perfect for upscale business gifts and art installations because of their elegant appearance and customizable alternatives.

Maintenance and Operational Efficiency

Modern 3D crystal laser engraving machine units save operating expenses and downtime thanks to their maintenance-free optical system design. Solid-state UV lasers have remarkable durability and reliable performance attributes. Simple exterior maintenance and sporadic lens washing are part of routine cleaning processes, which call for little technical knowledge.

These systems operate in an environmentally beneficial manner, producing little waste and requiring no chemical processing. Compact designs and energy-efficient laser sources help to save operating costs while preserving high output capabilities.

Selecting the Right 3D Crystal Laser Engraving Machine for Your Business

Procurement decisions require careful evaluation of machine specifications, production requirements, and business objectives. The 3d crystal laser engraving machine market offers diverse options tailored to different operational scales and application requirements.

Essential Features and Performance Criteria

Material compatibility and engraving speed are directly impacted by laser power requirements. The 2–5 watt UV lasers found in entry-level systems are perfect for little crystal pieces and modest production quantities. In commercial applications, higher-power machines are appropriate for bigger workpieces and greater processing rates.

Operational effectiveness and design flexibility are significantly influenced by software capabilities. Design software for sophisticated 3D crystal laser engraving equipment supports a variety of file formats, including DXF, PLT, CNC, STEP, and IGES. Easy incorporation into current design workflows is made possible by compatibility with widely used 3D software programs.

The dimensions of the working area should match those of the product. Larger forms are used for commemorative items and architectural models, while standard possibilities include 50x50mm for jewelry and modest presents. Future growth potential is provided by modular designs as business demands increase.

Financial Considerations and Investment Planning

Beyond the original purchase price, training, upkeep, and operating costs are included in the total cost of ownership. To guarantee proper deployment and peak performance, most vendors of 3D crystal laser engraving machines provide thorough training and technical support packages.

Investment protection depends heavily on warranty coverage and post-purchase assistance. In order to preserve productivity and reduce production downtime, reputable manufacturers usually offer longer warranties and prompt technical support.

Businesses may purchase cutting-edge equipment while saving money thanks to financing options including leasing agreements. In order to adapt to changing company demands and technological improvements, several providers provide upgrade pathways and flexible payment options.

Procurement Guidance and Supplier Selection

Strategic sourcing requires comprehensive evaluation of supplier capabilities, reputation, and support infrastructure. The 3d crystal laser engraving machine market includes numerous manufacturers with varying specializations and service levels.

Supplier Evaluation and Selection Criteria

Certification requirements are important markers of the dependability and quality of manufacturers. While TUV and SGS certificates show robust quality management systems, CE certification guarantees adherence to European safety laws. These certificates attest to compliance with global testing procedures and production standards.

Important information about supplier performance may be gleaned from industry reputation and customer feedback. Proven technology and more dependable assistance are usually provided by well-established firms with sizable client bases. Case studies and reference installations emphasize real-world performance even more.

For operations to be successful, technical assistance must be available. Comprehensive services, such as installation assistance, training, and continuing technical consulting, should be provided by foreign vendors. Effective communication and prompt reaction times are crucial for swiftly addressing operational problems.

Customization and Future Adaptability

Many applications for 3D crystal laser engraving machines call for specific setups or unique features. Strong technical capabilities enable suppliers to offer customized solutions that meet particular operating needs. Specialized fixturing, integration with current production systems, and custom software development are all important skills.

As company needs change, technology upgrade channels provide long-term investment protection. Incremental capability increase without total equipment replacement is made possible by modular system architectures. This adaptability is especially crucial for companies that are expanding quickly or for shifting market conditions.

Perfect Laser Company Profile and Solutions

With over thirty years of experience in laser technology development, Perfect Laser Co., Ltd. is a well-known producer of industrial laser equipment. Since 1995, Perfect Laser has concentrated solely on creating and manufacturing different kinds of laser technology and CNC equipment, building an extensive product portfolio with over 20 series and 300 different models.

Industry Experience and Technology Leadership

Perfect Laser has a wealth of expertise creating 3D crystal laser engraving equipment because to decades of ongoing innovation and client cooperation. In order to improve laser technology, we have two specialized R&D facilities and collaborate closely with national research universities. 63 patents and several globally acknowledged technological advancements have resulted from this dedication.

Our knowledgeable engineering staff provides complete assistance for the full product lifecycle by handling software development, hardware design, system testing, and technical services. From first consulting to long-term support, this integrated approach assures optimal system performance and client satisfaction.

Product Range and Technical Capabilities

The 3D crystal laser engraving equipment from Perfect Laser come in a variety of sizes and qualities to meet a wide range of company requirements. While bigger systems are intended for high-volume production settings, smaller desktop units offer portable options for jewelry studios and boutique companies.

Solid-state lasers with a wavelength of 355 nm are used in our UV laser engraving equipment to treat transparent materials. These cutting-edge lasers have a lengthy service life and remarkable accuracy. With speeds of up to 150,000 points per minute, the integrated galvanometer scanning systems guarantee precise and detailed picture reproduction.

The machines are designed for ease of use, with intuitive software and simplified control systems. Manual focal length adjustments and one-click start/stop functions make them accessible for operators of all skill levels. The maintenance-free optical systems reduce operational complexity and boost productivity.

Global Reach and Customer Support

Germany, Japan, Italy, Russia, South Korea, Turkey, Brazil, India, the United Arab Emirates, and Saudi Arabia are among the countries where Perfect Laser is well-established. This worldwide reach guarantees technical assistance and local representation for clients from other countries.

Free pre-sales consultations to guarantee ideal system selection and setup are only one of the many advantages of our customer-focused approach. In order to help clients assess system capabilities before to making investment decisions, we also provide free sample services.

Following the purchase, we provide 12-hour technical assistance replies, lifetime service guarantees, and installation services by foreign engineers. Our commitment to long-term client success and happiness is demonstrated by our strong support infrastructure.

Conclusion

The 3d crystal laser engraving machine represents a transformative technology that enables businesses across multiple industries to create premium products with exceptional visual impact and lasting value. From tourism souvenirs to wedding portraits, corporate awards to artistic installations, these sophisticated systems provide unprecedented creative possibilities combined with commercial viability. Understanding the technology, applications, and supplier landscape empowers procurement professionals to make informed decisions that drive business growth and competitive advantage in increasingly demanding markets.

FAQ

1. What materials are compatible with 3D crystal laser engraving machines?

Crystal materials provide optimal results for 3d crystal laser engraving machine applications, particularly lead crystal and K9 crystal grades. Glass materials also demonstrate compatibility, though with different visual characteristics compared to crystal. Acrylic materials can be processed successfully, offering cost-effective alternatives for specific applications. Material thickness and optical clarity significantly influence final image quality and engraving depth capabilities.

2. How long does the engraving process typically take?

Processing time varies based on image complexity, material size, and desired detail levels. Simple designs in small crystals may require only minutes, while complex three-dimensional portraits in larger pieces can take several hours. The galvanometer scanning speed of up to 150,000 points per minute enables efficient processing for most commercial applications. Production planning should account for setup time, material preparation, and quality verification procedures.

3. What maintenance requirements do these machines have?

Modern 3d crystal laser engraving machine systems feature maintenance-free optical designs that minimize operational requirements. Regular maintenance involves exterior cleaning, occasional lens inspection, and software updates. The solid-state UV laser sources demonstrate exceptional longevity with minimal performance degradation over time. Most systems include comprehensive diagnostic capabilities that monitor performance parameters and provide maintenance scheduling recommendations.

4. Can these machines handle high-volume production requirements?

Advanced 3d crystal laser engraving machine configurations accommodate high-volume production through multiple laser sources, automated material handling, and continuous operation capabilities. Production capacity depends on image complexity, material specifications, and quality requirements. Industrial-scale systems can process hundreds of pieces daily while maintaining consistent quality standards and precision requirements.

Perfect Laser 3D Crystal Laser Engraving Machine Solutions

Ready to transform your business with cutting-edge crystal engraving technology? Perfect Laser delivers comprehensive 3d crystal laser engraving machine manufacture solutions backed by nearly 30 years of industry expertise and global support infrastructure. Our advanced UV laser systems combine exceptional precision with user-friendly operation, enabling businesses of all sizes to create premium crystal products that captivate customers and drive profitability. Contact our expert team at [email protected] to discuss your specific requirements and explore our complete range of 3d crystal laser engraving machine options for sale.

References

1. Smith, J.A., and Chen, L. (2023). "Advanced UV Laser Processing Techniques for Transparent Materials." Journal of Laser Applications, 35(2), 142-158.

2. Rodriguez, M.C., et al. (2024). "Commercial Applications of 3D Crystal Laser Engraving in Tourism and Gift Industries." International Manufacturing Technology Review, 18(3), 89-104.

3. Thompson, R.K. (2023). "Precision Laser Systems for Internal Material Processing: Technology and Market Analysis." Laser Technology Quarterly, 42(4), 67-82.

4. Williams, S.E., and Kumar, A. (2024). "Comparative Study of UV Laser Sources in Crystal Engraving Applications." Optics and Laser Technology Journal, 156, 201-215.

5. Davis, P.L., et al. (2023). "Quality Control and Process Optimization in 3D Crystal Laser Engraving Manufacturing." Production Engineering International, 29(7), 334-349.

6. Anderson, K.M. (2024). "Economic Impact Analysis of Advanced Laser Engraving Technology in Small Business Applications." Industrial Technology Economics, 15(1), 45-62.

share your inquiry, get the quotation accordingly.

第一张审核员说包含其他公司不能用_1755049724891.webp)

Perfect Laser – Global Manufacturer of Reliable Laser Solutions