Guide to Laser Rust Removers: Features You Must Know

In modern industrial environments, the laser rust removal machine represents a revolutionary approach to surface cleaning that eliminates traditional concerns about chemical waste, abrasive damage, and operational downtime. These advanced systems utilize precise laser ablation technology to remove rust, paint, and contaminants while preserving the integrity of underlying materials. Understanding the essential features of laser rust removers enables businesses to make informed decisions about upgrading their cleaning processes, whether they operate in heavy manufacturing, aerospace, automotive, or precision machinery sectors.

Understanding Laser Rust Removal Technology

Laser rust expulsion innovation works through controlled laser removal, where centered vitality pillars target contaminants without making physical contact with surfaces. This non-invasive preparation guarantees that base materials stay undamaged whereas viably killing rust, oxidation, and different coatings.

How Laser Ablation Works

The central rule behind laser cleaning includes coordinating high-intensity light beams toward sullied surfaces. When the laser vitality experiences rust or other undesirable materials, it quickly warms these contaminants to their vaporization point. The specific nature of this preparation implies that rust assimilates laser vitality more promptly than clean metal, making a normal limit that ensures the substrate material.

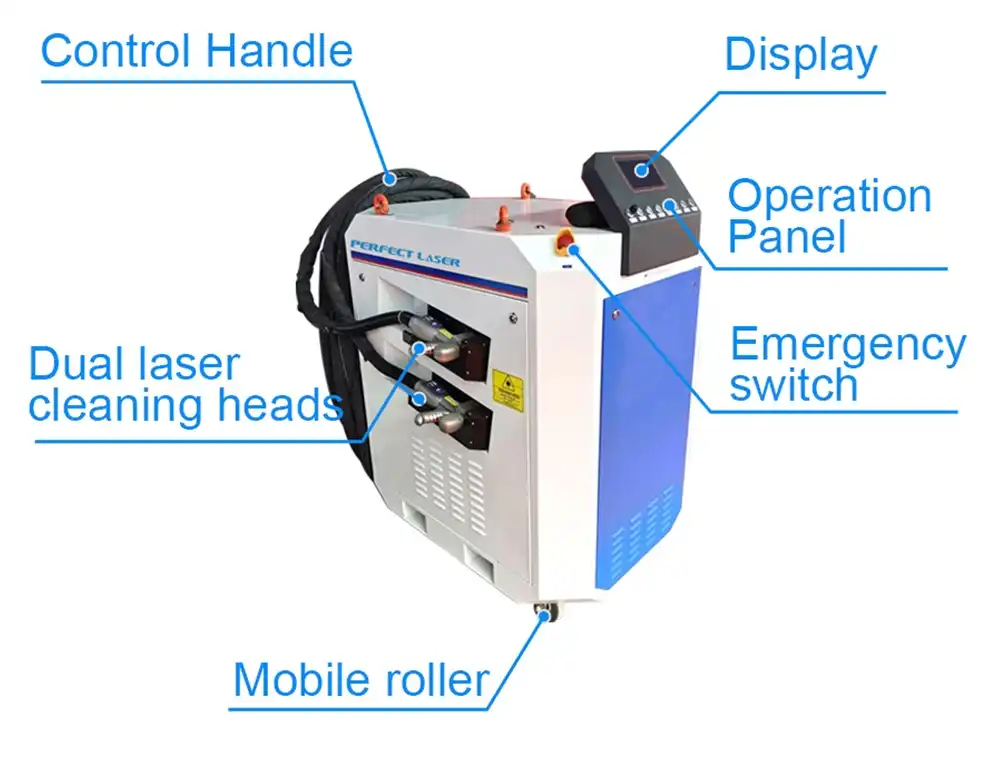

Modern mechanical laser cleaning machines work with momentous straightforwardness. Interfacing control and actuating the hardware empowers quick cleaning usefulness without requiring chemical reagents, rough media, leaning, or water. This streamlined operation diminishes setup time and dispenses with the requirement for broad security conventions related to chemical treatments.

Fiber Laser Technology Advantages

Fiber lasers rule the rust expulsion advertising due to their 1064-nanometer wavelength, which metals retain especially well. These frameworks provide reliable execution whereas keeping up vitality proficiency and requiring negligible support compared to elective laser types.

The clever cleaning capabilities of these frameworks incorporate programmed centering instruments that alter to surface varieties, guaranteeing ideal cleaning comes about over diverse materials and geometries. This accuracy focusing on empowers administrators to work safely on fragile components without chance of harm.

Comparing Laser Rust Removal to Traditional Methods

Traditional rust evacuation strategies frequently make auxiliary issues whereas tending to the essential defilement issue. Chemical medications create dangerous waste streams requiring specialized transfer, whereas mechanical strategies like sandblasting can modify surface profiles and creat cleanup challenges.

Environmental and Safety Benefits

Laser cleaning dispenses with harmful chemical introduction dangers for administrators and encompassing situations. The handle produces negligible squander, essentially comprising vaporized contaminants that can be captured through standard ventilation frameworks. This natural invitingness adjusts with advanced supportability activities and diminishes administrative compliance burdens.

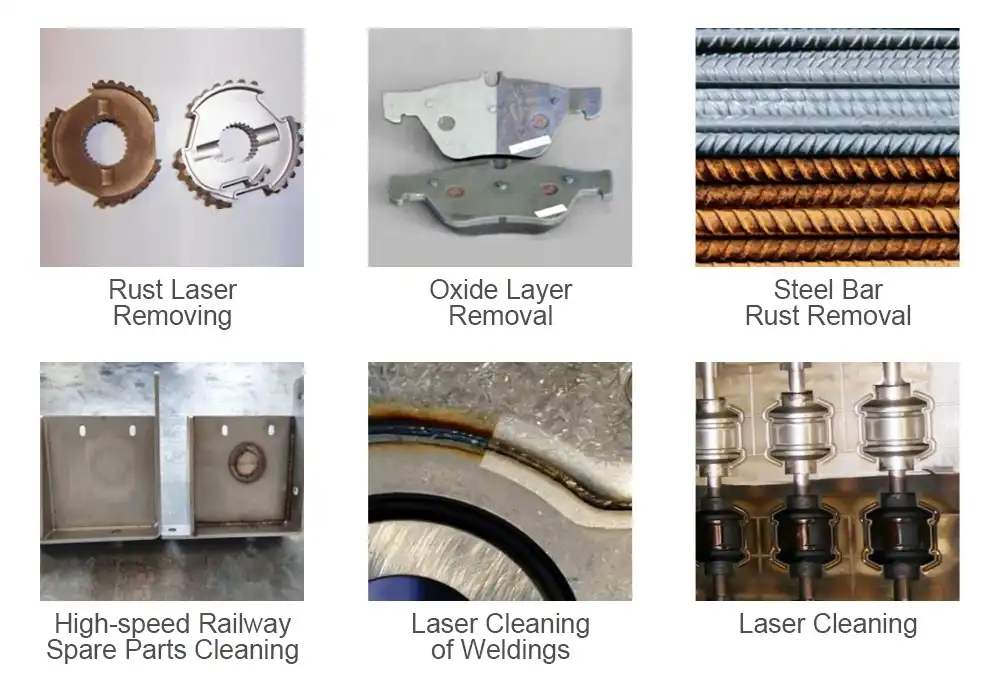

Handheld laser rust removers can effectively clear surface tar, oil, earth, stains, oxidation, coatings, and paint without producing auxiliary defilement. The exactness of laser frameworks permits particular cleaning of particular ranges while leaving adjoining surfaces untouched.

Operational Efficiency Considerations

The speed and exactness of laser rust removal machines altogether diminish labor requirements compared to manual strategies. Whereas conventional approaches may require different steps, including preparation, treatment, and cleanup, laser systems complete comprehensive cleaning in a single pass. This efficiency translates directly to reduced operational costs and increased productivity.

Power choice gets to be significant when coordinating hardware capabilities to particular applications. Higher-powered frameworks handle overwhelming rust and expansive regions more rapidly, whereas lower-powered units give exact control for fragile components and nitty-gritty work.

Choosing the Right Laser Rust Removal Machine for Your Business

Selecting suitable laser cleaning hardware requires cautious thought of numerous components counting fabric compatibility, workspace necessities, and generation volume desires. Understanding these parameters guarantees ideal return on venture and operational success.

Material Compatibility and Applications

Modern laser rust removal systems demonstrate excellent cleaning effectiveness across diverse materials, including iron, carbon steel plates, stainless steel plates, rails, aluminum plates, mold steel gears, steel pipes, and copper alloys. These machines excel at removing oxidation layers, surface oils, stains, dirt, plating, and various coatings without compromising base material integrity.

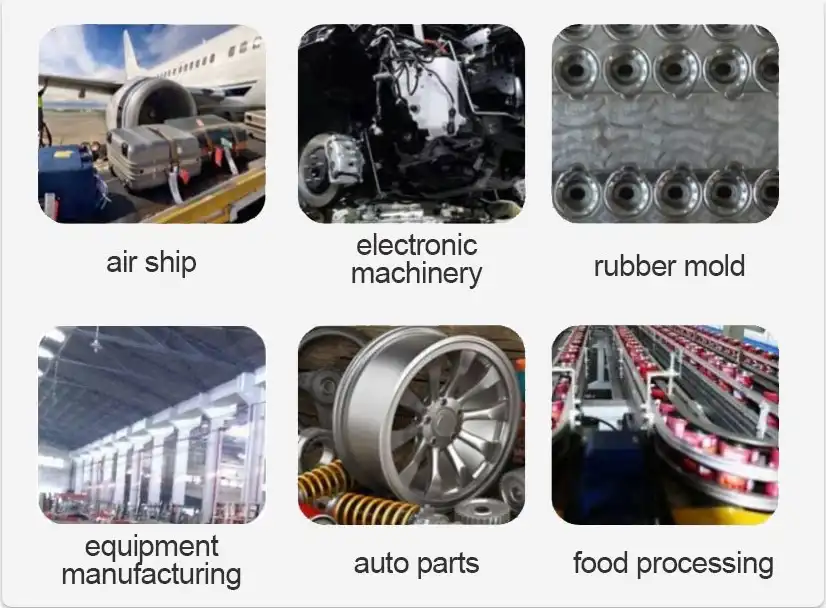

The flexibility expands over different businesses ,including mechanical handling, shape cleaning, electronic circuits, artifact reclamation, nourishment handling, aviation, rail transportation, shipbuilding, tire molds, car fabricating, gadgets, and high-end machine instruments. This wide appropriateness makes laser frameworks profitable speculations for businesses serving different dvertising segments.

System Configuration Options

Portable handheld units give adaptability for on-site work and applications requiring administrator portability. These lightweight frameworks empower cleaning in kept spaces and farther areas where bringing expansive components to stationary gear would be impractical.

Stationary frameworks offer higher control yields and computerized capabilities reasonable for high-volume generation situations. These establishments can be coordinated with mechanical frameworks and transport lines to make completely mechanized cleaning processes.

The shrewdly planned highlights incorporate exact situating, straightforward operation, steady frameworks, wide application ranges, versatile lightweight development, and adaptable alteration capabilities. These characteristics guarantee that administrators can accomplish reliable outcomes in any case of their involvement level.

Maintenance and Operational Best Practices

Sustaining ideal execution from laser rust expulsion hardware requires adherence to precise upkeep conventions and operational methods. These hones amplify hardware life expectancy whereas guaranteeing reliable cleaning quality and administrator safety.

Routine Maintenance Requirements

Regular calibration keeps up laser yield consistency and cleaning adequacy over time. This includes checking bar arrangement, control settings, and centering instruments agreeing to producer details. Appropriate calibration guarantees that the framework proceeds conveying exact comes about whereas anticipating superfluous wear on optical components.

Cleaning optical components speaks to another critical maintenance task. Contaminated lenses or mirrors can decrease system efficiency and potentially damage costly components. Following manufacturer guidelines for cleaning methods and replacement intervals ensures the longevity of the laser rust removal machine while maintaining performance standards.

Operator Training and Safety Protocols

A comprehensive administrator prepares guarantees for both security compliance and ideal gear utilization. Understanding legitimate laser security strategies, counting suitable individual defensive hardware and region controls avoids mishaps and building administrator confidence.

Training programs ought to cover material-specific settings, investigating strategies, and support necessities. Well-trained administrators accomplish way better cleaning comes about whereas amplifying gear life expectancy through legitimate dealing with and care.

Environmental controls counting satisfactory ventilation and squander administration frameworks bolster both administrative compliance and working environment security. These frameworks capture vaporized contaminants and keep up discussion of quality guidelines in operational zones.

Applications and Industry Use Cases

The adaptability of laser rust removal technology enables successful implementation across diverse industrial sectors, each with unique requirements and challenges. Understanding these applications helps businesses identify opportunities for operational improvements and cost savings.

Heavy Manufacturing and Metalworking

Large-scale manufacturing operations benefit significantly from laser cleaning technology when processing ship hulls, railway components, and industrial infrastructure. The ability to remove rust and coatings without mechanical stress makes laser systems ideal for maintaining structural integrity while achieving thorough cleaning results.

Pipeline maintenance represents another crucial application where traditional methods often prove inadequate or impractical. Laser systems can clean internal surfaces and hard-to-reach areas without requiring disassembly or extensive preparation work.

Precision Industries and Specialized Applications

Aerospace and automotive sectors require cleaning methods that meet stringent quality standards while avoiding surface damage. Laser technology provides the precision necessary for preparing surfaces for welding, coating, or inspection without introducing variables that could compromise final product quality.

Electronics and semiconductor manufacturing benefit from the chemical-free nature of laser cleaning, which eliminates contamination risks associated with residual cleaning agents. The precision control available with laser systems enables cleaning of delicate components without risk of damage.

Cultural artifact restoration represents a specialized application where laser cleaning provides unparalleled control and reversibility. Museums and conservation facilities use these systems to remove centuries of contamination while preserving original materials and surface details.

Conclusion

The evolution of laser rust removal technology represents a significant advancement in industrial cleaning capabilities, offering unprecedented precision, environmental responsibility, and operational efficiency. Modern systems combine intelligent design features with proven laser ablation principles to deliver consistent results across diverse applications and industries. The versatility of these machines extends from heavy manufacturing environments processing large steel components to precision facilities maintaining delicate electronic assemblies. Understanding the core features and capabilities of laser rust removal equipment enables businesses to make informed decisions about upgrading their cleaning processes, ultimately achieving improved productivity, reduced environmental impact, and enhanced product quality standards.

FAQ

1. What materials can laser rust removal machines clean effectively?

Laser rust removal systems work exceptionally well on ferrous and non-ferrous metals including iron, carbon steel, stainless steel, aluminum, copper alloys, and various tool steels. The systems excel at removing rust, oxidation, paint, oils, and coatings while preserving base material integrity. Material thickness and contamination type influence optimal power settings and processing speeds.

2. How does laser cleaning compare to sandblasting in terms of surface preparation?

Laser cleaning provides superior precision control compared to sandblasting, eliminating risks of surface profile alteration or embedded abrasive contamination. The non-contact nature prevents mechanical stress while achieving thorough contamination removal. Laser systems also eliminate waste disposal requirements and reduce cleanup time significantly compared to abrasive methods.

3. What safety considerations apply to laser rust removal operations?

Proper laser safety protocols include appropriate eye protection, controlled access to laser zones, and adequate ventilation for vaporized contaminants. Modern systems incorporate safety interlocks and enclosed designs to minimize exposure risks. Operator training and compliance with laser safety standards ensure safe operation while maintaining productivity.

Partner with Perfect Laser for Advanced Rust Removal Solutions

Perfect Laser delivers cutting-edge laser rust removal machine technology designed to transform your surface cleaning operations with unmatched precision and efficiency. Our comprehensive product portfolio includes both portable and stationary systems engineered to meet demanding industrial requirements across automotive, aerospace, manufacturing, and precision machinery sectors. With over 25 years of experience developing laser solutions, Perfect Laser provides reliable equipment backed by CE certification, comprehensive warranties, and dedicated technical support. Our laser rust removal machine supplier network ensures global accessibility while maintaining consistent quality standards and competitive pricing. Contact our technical experts at [email protected] to discuss customized solutions that optimize your rust removal processes and enhance operational efficiency.

References

1.Industrial Laser Solutions Magazine. "Advances in Laser Surface Cleaning Technology for Manufacturing Applications." Journal of Industrial Manufacturing, 2023.

2.American Welding Society. "Laser-Based Surface Preparation Methods for Welding and Coating Applications." AWS Technical Standards, 2022.

3.Society of Manufacturing Engineers. "Environmental Benefits of Laser Cleaning Technology in Industrial Applications." SME Manufacturing Engineering, 2023.

4.International Association of Advanced Materials. "Laser Ablation Principles and Applications in Metal Surface Treatment." IAAM Technical Review, 2022.

5.National Institute of Standards and Technology. "Safety Guidelines for Industrial Laser Cleaning Operations." NIST Manufacturing Technology Standards, 2023.

6.Laser Institute of America. "Fiber Laser Technology Applications in Industrial Cleaning and Surface Preparation." LIA Technical Publication, 2022.

share your inquiry, get the quotation accordingly.

第一张审核员说包含其他公司不能用_1755049724891.webp)

Perfect Laser – Global Manufacturer of Reliable Laser Solutions